Strategic Wood Security through Digital Root Standing & AI-Driven Inventory

Produced by: Arboair

Date: November 2025

Topic: Digital Transformation in Final Felling & Inventory

The European forestry industry stands at a critical juncture. After decades of relying on stochastic models, statistical extrapolations, and manual sampling, the sector is facing an irreversible paradigm shift toward deterministic, data-driven methods. This whitepaper validates the transition from manual "Digital Root Standing" (Digital Rotstämpling) to AI-powered analysis, demonstrating how modern photogrammetry offers a commercially superior alternative to traditional methods.

Current manual inventory methods suffer from error margins of 20–40% regarding volume. In an era of tight margins and strict regulatory requirements (EUDR), this level of uncertainty is no longer sustainable. Arboair’s solution, utilizing advanced AI algorithms on drone-captured RGB data, shifts this reality from estimation to precision.

Key Findings in this Report:

This report serves as a technical and economic validation of Arboair’s technology, designed for decision-makers seeking to secure wood supply, ensure compliance, and maximize yield.

Traditional forest inventory is inherently "stochastic." It relies on sampling 1-5% of a forest area and assuming these sample plots perfectly represent the biological diversity of the entire stand. In reality, nature is rarely uniform. This methodology introduces systematic errors that propagate through the entire supply chain.

When a harvester arrives at a site with inaccurate data, logistics crumble. Transport trucks are either overbooked (wasted fuel) or underutilized (wasted capacity). More critically, without precise data on individual tree geometry before harvesting, the bucking (aptering) process is reactive rather than proactive.

"Making multi-million Euro decisions based on data with a 40% error margin is a risk profile that few other modern industries would accept."

Furthermore, the administrative burden is increasing. The EU Deforestation Regulation (EUDR) demands 100% traceability and geolocation. Manual methods, costing approximately $15-30 per m³ for due diligence, are becoming prohibitively expensive compared to digital alternatives (for a fraction of the cost).

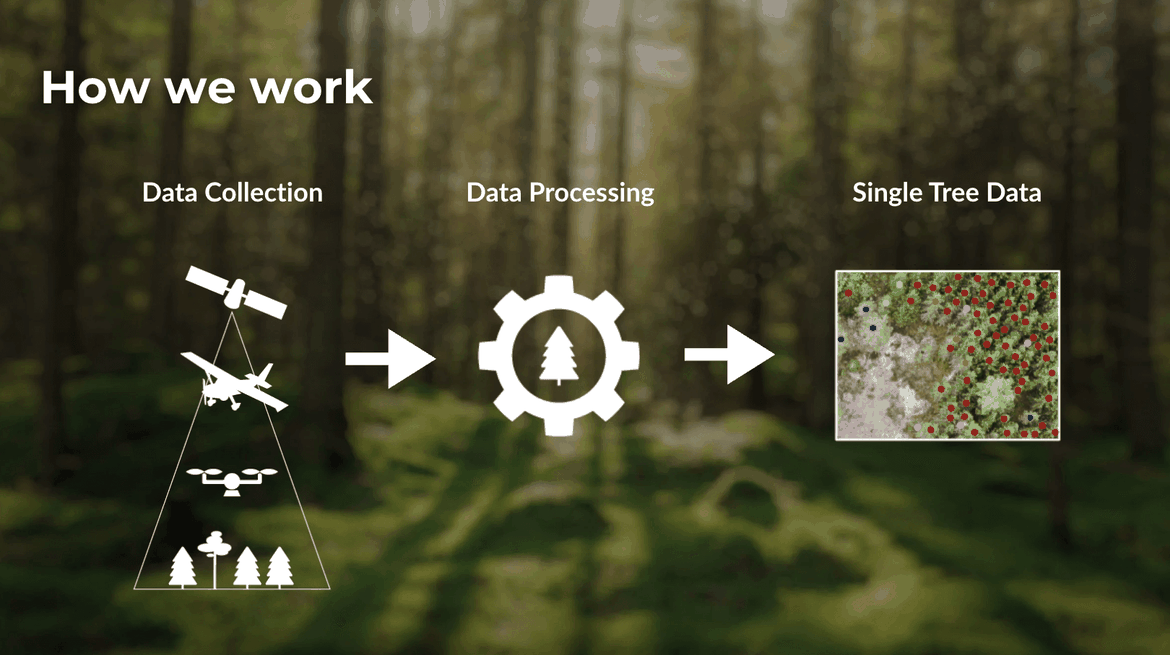

Arboair has developed a proprietary software ecosystem that transforms standard drone imagery into high-precision forest intelligence. Unlike heavy LiDAR systems that require expensive manned aircraft or heavy-lift drones, Arboair utilizes RGB Photogrammetry combined with advanced AI.

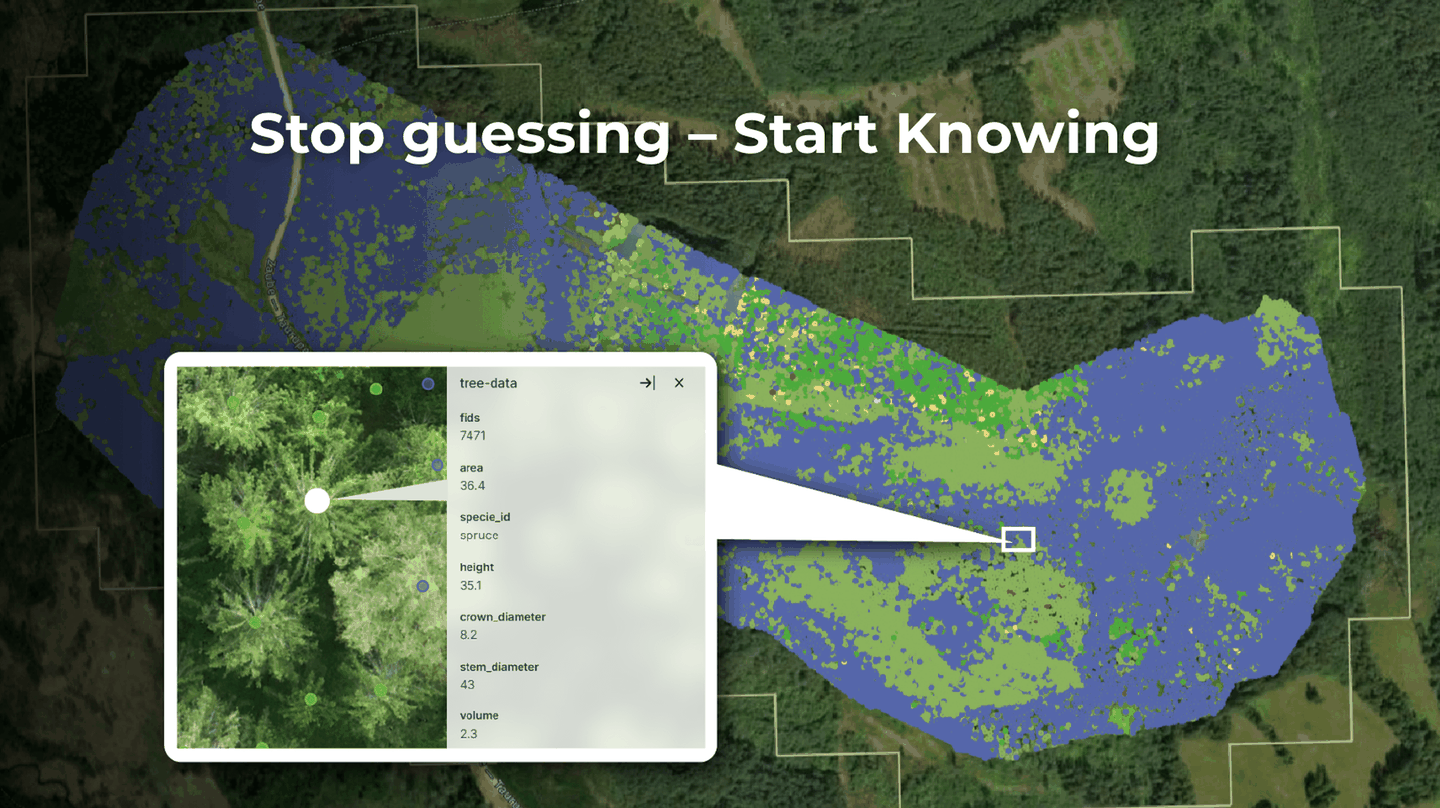

The technology creates a "Digital Twin" of the forest stand. Our AI models identify and classify individual trees in collected data, achieving high accuracy. Beyond simple counting, the models extract:

While LiDAR has historically been the "gold standard" for ground models, modern analysis proves that RGB photogrammetry offers equivalent operational precision for final felling at a fraction of the cost (up to 70% lower data collection costs). By combining drone canopy data with existing national Digital Terrain Models (DTM), Arboair achieves the "best of both worlds": high-resolution spectral data and accurate height readings.

The true test of any technology is field validation. In collaboration with a customer, Arboair’s technology was rigorously tested across multiple tracts, comparing digital analysis against Harvester Production Reports (HPR)—the "absolute truth" of what was cut.

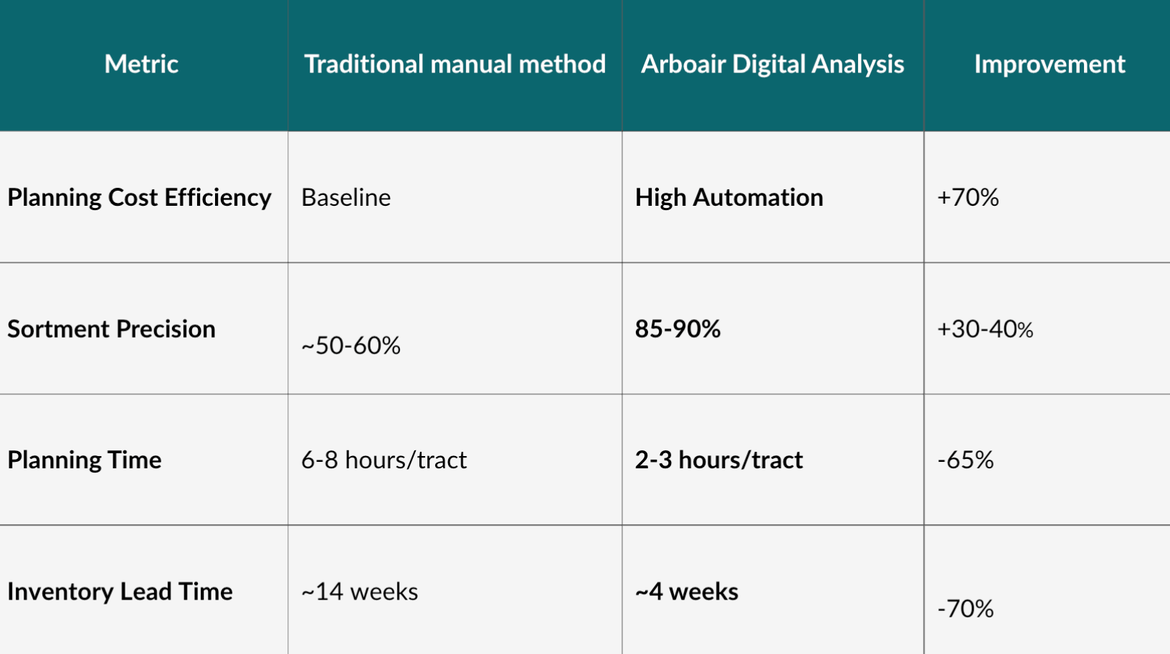

The results demonstrate a radical improvement over traditional subjective estimation. Where manual visual estimation often results in sortment precision around 50%, the digital analysis achieved levels up to 90%.

Data confirms that over 80% of the analyzed tracts fell within ±15% of the total sortiment volumes, with the absolute mean error for volume hovering around below 10%. For the critical DBH (Diameter) measurement, which dictates the price of the log, the error margin was reduced to a bit over ±2cm on individual trees.

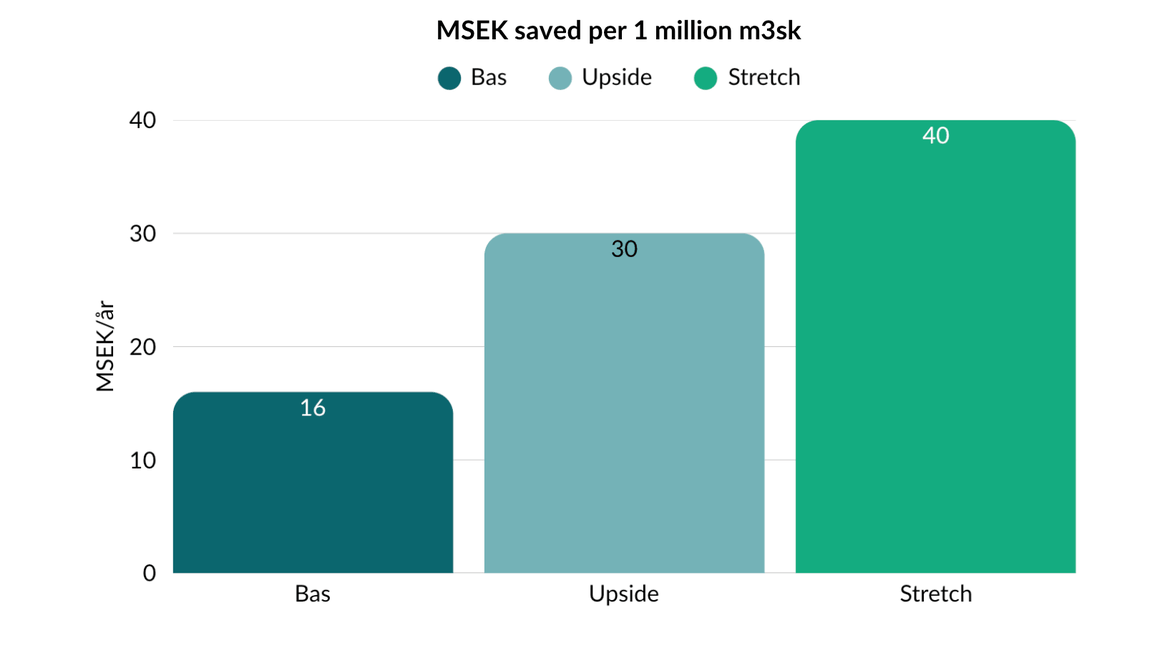

Moving beyond technical accuracy, the economic implications of implementing Arboair’s solution are profound. The "Consolidated Deep Dive Analysis" (Djuplodsanalys) highlights that the shift to digital is not just about saving time—it is about unlocking trapped value.

By moving from Stochastic to Deterministic forestry, we eliminate the risk premiums currently built into timber prices due to uncertainty. The value potential for the European market is estimated at €5.0 - 10.1 billion annually.

The ROI is driven by three main levers:

Arboair’s solution also acts as a compliance shield. With EUDR requirements, the ability to provide visual, geolocated proof (polygons) of the forest state prior to felling is mandatory. Digital inventory reduces the risk of fines (up to 4% of turnover) and dramatically lowers the cost of compliance.

Furthermore, by optimizing the bucking process digitally, we ensure that fewer trees are harvested to meet the same industry demand—a direct contribution to sustainable forestry.

The data is clear: The era of estimating forest value is over. The era of measuring it has begun.

Arboair’s Digital Root Standing solution offers a verified, scalable, and economically superior alternative to traditional methods. By leveraging drone photogrammetry and AI, the forest industry can reduce operational costs by 70%, increase sortment precision to 90%, and secure millions in formerly lost revenue.

Don't let uncertainty dictate your margins. Implement deterministic forestry today.